From bolt to fastening system:

Chronology of a family business

1884

Foundation of a small trades Business in the prospering Ruhr industry by the Essen blacksmith August Friedberg who names it “Rotthauser Schrauben- und Nietenfabrik” (Rotthausen’s bolt and rivet factory)

1891

Located in the direct neighborhood of its customers from the mining industry and the related heavy industries in the emerging Ruhr area, the trades business gradually grows into an industrial enterprise with a warehouse, in-house production instructions and an ever increasing customer base.

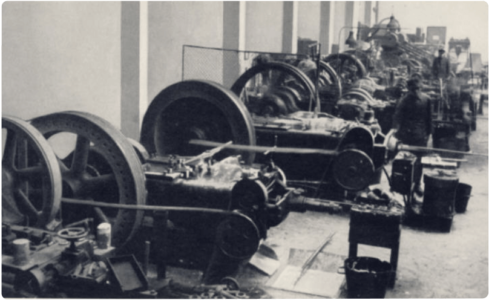

1899

Shortly before the turn of the century general production standards for bolts have been developed for the first time. Machine production gains in importance and the erection of a boiler house symbolizes the dawning of a new age. The industries along the rivers Rhein and Ruhr gain ground. Friedberg keeps up with them.

1905

Upon incorporation with the Local Court the company name “Schraubenfabrik August Friedberg” (Bolt Factory August Friedberg) was coined.

1924

Managed by the son of the company founder, Dipl. Ing. Gustav Friedberg, the company experiences a phase of dynamic growth, followed by the difficult years of the Great Depression, which also leave their mark. Lacking orders the production temporarily comes to a standstill, before demand picks up again.

1934

By this time the company has returned to full operation and employs 140 people working at its facilities in Gelsenkirchen. On April 19, the company founder August Friedberg dies at the age of 81.

1945

During World War II 80% of the company premises have been destroyed. Reconstruction lasts until the 1950s. The company has to overcome many obstacles and jump through many hoops before its success story continues in a newly flourishing post-war Germany.

1959

On the 75th anniversary of the company Friedberg in 1959 a news article in “Westdeutsche Allgemeine Zeitung” states that the company represents an era in economic history. As a manufacturing company for the mass production of bolts and rivets and as a family business it has been lucky to keep its independence.

1966

Following the first economic crisis of the young republic many coal mines not only in the Ruhr area are closing down, thus reducing the Friedberg customer base by a whole industry. In spite of this crisis, which also strongly affects the city of Gelsenkirchen, Friedberg decides to expand its premises located in Belforter Straße to 25000 square meters.

1971

The third generation in the family takes over the helm. The company, whose premises have now grown to over 30000 square meters, is henceforth headed by the graduate economist Dipl.-Oec. Ingrid Brand-Friedberg, who expands the business further and begins to realign it, including production processes and equipment, so as to attract more international customers.

1976

The direct export share of the parent company in Gelsenkirchen amounts to over 50% of the turnover.

1980

The rapid reorganization into an internationally active specialized manufacturer of high-value connecting technology is being continued. Research and development are gaining in importance and so do aspects like quality, logistics, services and technical advice. The transformation into a global business is also spurred on by new industries, which are successfully conquered as key markets.

2000

The new millenium sees the company AUGUST FRIEDBERG as a much valued player in the global market for fastening systems. Last but not least, this is thanks to the increasing demand from the wind energy industry.

2014

With a history of now 130 years the company is one of the oldest family businesses in Germany and still on a winning streak. Next to automotive products it is especially the wind bolts, demanded from the rapidly growing market for renewable energies, which give a major boost to the company’s technological development and production capacity.

2015

Upon the death of the long-term owner and general manager of the company, Ingrid Brand-Friedberg on February 4, Beatrix Brand from the fourth generation takes over responsibility for the continuously growing family business.

2017

Changes and modernizations, new structures and further improved standards characterize the image of a company, which considers itself well-prepared for all future technical and economic requirements. The tradition will be continued: Manufacturing strong connections and high-quality products for demanding industries and applications. The reliability of a family business passed on for generations remains one of the pillars of a customer-focused business policy.